PRINCIPLES AND PILLARS

WASTE TO ENERGY

INTRODUCTION AND DANGERS

ABSTRACT: The circular economy is a transformative business model that offers sustainability, innovation, and competitiveness by redefining our approach to markets, customers, and natural resources. Key terms like sharing, reuse, and recycling underscore the importance of technological innovation and environmental sustainability. Pillars of the circular economy include sustainable resources, products as a service, sharing platforms, extended life service, and reuse and new lifecycles. The energy transition and circular economy are intertwined, emphasizing energy efficiency and renewable resources. Waste to energy technologies play a crucial role in the circular economy, utilizing waste as a resource for biofuels, heat, and electricity. However, there are dangers associated with waste to energy plants, including air pollution and waste management challenges. As companies embrace the circular economy, it’s crucial to mitigate risks like transformer explosions, which can disrupt energy production and harm the environment. Incorporating preventive measures like the transformer protector (tp) enhances safety and contributes to a more sustainable energy infrastructure.

The Circular Economy is more than just a buzzword; it’s a transformative business model that holds the key to sustainability, innovation, and competitiveness. At its core, the Circular Economy seeks to redefine our approach to markets, customers, and natural resources, leading to significant competitive advantages such as reduced costs, efficient energy use, decreased CO2 emissions, and optimized supply chains.

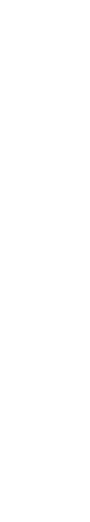

Key terms associated with the Circular Economy include sharing, loan, reuse, repair, reconditioning, and recycling. These concepts underscore the importance of technological innovation, environmental sustainability, energy efficiency, and the use of renewable resources in creating a new, virtuous economic system.

The Pillars of the Circular Economy are:

- Sustainable Resources: Prioritizing the use of renewable inputs to reduce reliance on finite resources.

- Products as a Service: Introducing new categories of products that are designed to be reused, repaired, or recycled.

- Sharing Platforms: Facilitating the sharing of products or services to maximize their use and minimize waste.

- Extended Life Service: Prolonging the lifespan of products through repair, refurbishment, and remanufacturing.

- Reuse and New Lifecycles: Creating new value from products and materials by reintroducing them into the market through reuse or recycling.

The energy transition and the transition to a circular economy are intertwined. The circular economy emphasizes using energy efficiently, reducing primary energy consumption, and utilizing waste heat and renewable energy sources. This approach not only conserves energy but also reduces environmental impact.

Global energy demand is on the rise, making energy efficiency a critical consideration. Improving energy efficiency in industrial processes requires both technological upgrades and process innovations to consume as little energy as possible.

Renewable energy, such as solar and wind power, aligns with the circular economy’s principles by using infinite resources that are not consumed during energy generation. Biomass energy sources, though limited, can be cultivated repeatedly with proper management.

Waste Heat and Industrial Synergy.

Waste heat from industrial processes can be repurposed, reducing the need for additional energy sources. This approach exemplifies the circular economy’s focus on maximizing resource use and minimizing waste.

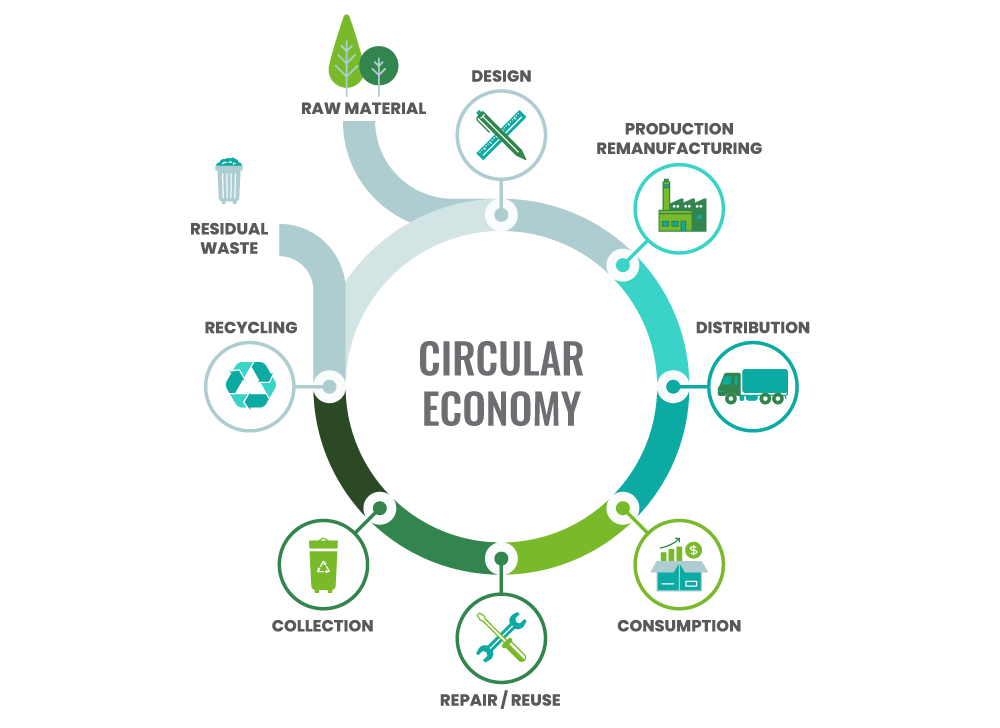

The Waste to energy technologies complies direct and indirect with most the principles announced, making of it one of the most attractive subjects to analyze. Why this technology is so important?

- It is based on an ever-growing “resource” mass produced by humans everywhere and, therefore it can be considered sustainable. According to the US Department of Energy, Biotechnologies Office: “Wet waste, solid waste, and gaseous waste streams are potential high-impact resources for the domestic production of biofuels, bioproduct precursors, heat, and electricity. Wastes represent a significant and underutilized set of feedstocks for renewable fuel and product generation.[1]”.

Different from other renewable sources.

- Without introducing any new product to the market, this technology intervenes one of the most used services around the world: the electricity. And it does it, applying the most important principles of the circular economy which are: reuse of things, minimize waste by using it to produce energy, and consequently extends the lifespan of products by using them as raw materials to produce the needed energy.

But how exactly a waste to energy plant works?

According to the U.S. Energy Information Administration (EIA)

“Waste-to-energy plants burn municipal solid waste (MSW), often called garbage or trash, to produce steam in a boiler, and the steam is used to power an electric generator turbine.

MSW is a mixture of energy-rich materials such as paper, plastics, yard waste, and products made from wood. For every 100 pounds of MSW in the United States, about 85 pounds can be burned as fuel to generate electricity. Waste-to-energy plants reduce 2,000 pounds of garbage to ash that weighs between 300 pounds and 600 pounds, and they reduce the volume of waste by about 87%.

The most common waste-to-energy system in the United States is the mass-burn system. In this system, unprocessed MSW is burned in a large incinerator with a boiler and a generator to produce electricity. A less common type of system processes MSW to remove noncombustible materials to produce refuse-derived fuel (RDF).[2]”.

All the initiatives we have studied so far are linked to the generation segment inside the energy world. Companies must pay the most attention to all measures on hand to prevent disasters like transformer explosions, which could compromise the financial stability of the project by cutting the energy production outcome. They could also harm the project’s reputation due to damages done to the environment, such as a leak in a water source or a protected ecosystem. And if the generation project is founded on circular economy parameters, and incident of these kind would carry the most nefarious consequences, because it can stop to produce the needed clean energy; and could produce harm to the environment which are the main purpures of this kind of initiatives.

Transformer explosions and fires have significant consequences on generation plants, as evident in recent news. For instance, Entergy’s Waterford 3 nuclear generating plant in Killona had to shut down after two transformers caught fire in its main transformer yard. This forced a shutdown of the reactor and an emergency declaration, highlighting the potential dangers and disruptions caused by such incidents. In a statement released on Transformer Magazine, Mike Bowling, Entergy Nuclear Communications Manager indicates: “The plant remains offline in a safe, stable and secure position while repair schedules are made and completed. We cannot discuss when the plant will return to operation as that is business-sensitive information. We can say that the related work should take several weeks to complete,”[3].

Beyond the immediate impacts on energy production, transformer explosions and fires can have far-reaching consequences. They pose risks to human life, as many employees work in proximity to transformers, and can lead to environmental pollution, especially when plants are situated near water bodies. Additionally, transformers housed in vaults or indoor locations introduce supplementary safety concerns for personnel.

Moreover, transformer incidents can disrupt power supply to communities, causing inconvenience and potential dissatisfaction among consumers. Stock market fluctuations can also occur, as transformer failures can negatively impact the stock market, influencing the overall financial stability of power plants.

In conclusion, the Circular Economy principles align closely with the need for preventive measures like TRANSFORMER PROTECTOR (TP) in the energy sector. By prioritizing sustainable resources, products as services, and extended product life cycles, the Circular Economy sets a framework for minimizing waste and maximizing efficiency. Incorporating solutions like TP not only enhances the safety and reliability of power generation but also contributes to a more sustainable and resilient energy infrastructure. Power generators can embrace these principles to not only mitigate risks but also to promote a greener and more sustainable future for the energy industry. Secure your assets today with the TRANSFORMER PROTECTOR and safeguard your key assets from potential threats, while contributing to a more circular and sustainable economy.

Secure your assets today with the TRANSFORMER PROTECTOR and safeguard your key assets from potential threats.