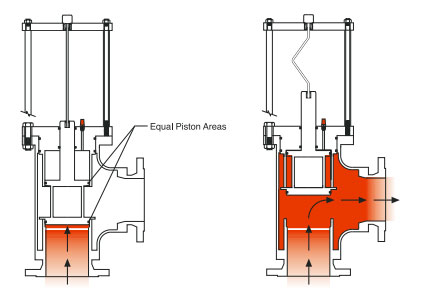

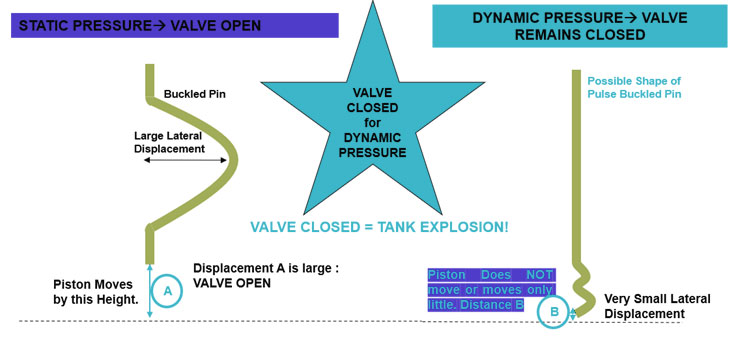

After thorough legal review, TRANSFORMER PROTECTOR CORPORATION was confirmed as the patent holder for Rupture Pin Valve Technology. However, in alignment with our commitment to innovation and safety, we have chosen not to promote, recommend, market, or manufacture this technology. Extensive studies and industry research have highlighted limitations in the effectiveness of Rupture Pin Valve Technology in preventing transformer explosions and fires. Specifically, it has been determined that this system is not well-suited to prevent a transformer’s tank from exploding in the event of low impedance failure, which generates in all cases a significant dynamic pressure within the tank.